pulse jet bag filter design calculation

PULSE JET BAG FILTER DESIGN - PULSE JET BAG FILTER DESIGN Flow gas rate Temperture Concentration of the dust in gases Average diameter of the particle | Course Hero

PULSE JET BAG FILTER DESIGN - PULSE JET BAG FILTER DESIGN Flow gas rate Temperture Concentration of the dust in gases Average diameter of the particle | Course HeroEnter Any Riveters hand useful for leather work? For , 31 October 2012 in Recommended posts I've been at Harbor Freight a couple of times lately, and I wonder about hand rivets and wonder if they'd use leather. The rice paddies look like a whole can of worms in general and I need to investigate what kind of rivets I would need to get but I'm thinking about things like copper rivets, etc. (like jeans and boots but in leather in general). Various sizes of rivets would be important - does anyone know if those hand riveters on HF would work for this? Until I can get a more professional one anyway. Share this post Hello Doug.. You mean rivet pop guns? Like this? I think they can work, depending on the application and as long as you put the reinforcement washers too. Earlier this year, my motorcycle panniers burned to the content, after they began to overflow over my escape with all the rain we had here. I made plastic backup panels for them, then glued and also used pop rivets to keep them on. They've done the trick so far. I just used some extra wide-angle rivets on the plastic side and stainless steel washers on the back, so they wouldn't pull the leather. The main thing I'm gonna say about using that kind of rivet is that the back of them is as ugly as someone else's baby, IMHO, so make sure it's not in sight. RegardsPhilps. There are also beautiful versions of babies from other people available.. Share this post I agree with everything Phil said, and I'll add that you can hook them up a little... in a modern art sense of the beautiful. Share this post FWIW of the gruñón; I don't care much about the pop-rivets at all - much less working with leather. Springfield Leather has antique rivets and copper rivets and burs in a couple of sizes. They end up looking like that. Mike Share this post Yeah, I guess the pop-riveter probably isn't the way to go then.. I want it to look good on both sides. Now, those of that Holster look great! Share this post You use the rivet set (one tool, not a group of things) that you can buy from Springfield leather or other providers. It only matches the size of the set to the size of the rivet. I use #9-size rives on the rare occasion I happen to need them. Mike Share this post You use the rivet set (one tool, not a group of things) that you can buy from Springfield leather or other providers. It only matches the size of the set to the size of the rivet. I use #9-size rives on the rare occasion I happen to need them. Mike. You use the rivet set (one tool, not a group of things) that you can buy from Springfield leather or other providers. It only matches the size of the set to the size of the rivet. I use #9-size rives on the rare occasion I happen to need them. Mike I'm not finding an individual tool (single point) used for rivets when searching for their site with the set of "rivet set". Maybe you were meaning the "Rivet Setter" that appears a single article (that you hit with a hammer) but I think that even that needs a bad under it. Regardless... I think what interests me most is the rivet setter type manual mounted press bank, of course you can get old used in ebay for much cheaper (usually the Rex brand etc.). But I'm confused about it. They are extra pieces necessary to make a variety of rivet sizes (like several die or whatever) - Does anyone know? Springfield adds that it mentions a death by line 20 snaps but what about the different rivet sizes? And if so, could those pieces still be source somewhere? Share this post There are multiple tubular rives of size and ready for which the press could be used. It's not for copper rivets. Quick rivets and tubular rivets can be pressed. Copper rivets need to be trimmed and greased with a hammer and rounded with the down tool outlet. For #9 copper rivets the tool you need is this. You can also get it from the spring field. search for rivet setter instead of establishing. Share this post HellfireJack is right. I don't know why they added the 'er' at the end of the 'set' of rivet - - it has been called a 'set' for as long as I have known of them, and I have used all the sizes of rivets and burrs over the years - mainly on the farm team, but now and then in leather. As far as I'm concerned, if you really need a leather rivet, the coppers are what you use. Those 'Speedy' rivets, or the quick rivets have been known to separate. Mike Share this post ... As far as I'm concerned, if you really need a leather rivet, the coppers are what you use. ... As far as I'm concerned, if you really need a leather rivet, the coppers are what you use. I agree above all, but there are some elements in which the "doble cap" rivets are aesthetically better for finer items. So... one of these hands presses for double rivets and a "set" hammer for the copper rivet and... Or does anyone know for sure whether the copper rivet and the burr style can or cannot be cut and greased after being established with a hand press? I ask, because I used the "sets" hammer style on snaps and eyelets/grommets with less than perfect results. Which is a great reason I started looking for a better choice. Share this post That little nanny probably wouldn't handle the copper rivets too well. I wouldn't use anything less than a tonne press. Maybe if ease and appearance are what you're looking for Chicago screws could be easier an option? Share this post That little nanny probably wouldn't handle the copper rivets too well. I wouldn't use anything less than a tonne press. Maybe if ease and appearance are what you're looking for Chicago screws could be easier an option? That little nanny probably wouldn't handle the copper rivets too well. I wouldn't use anything less than a tonne press. Maybe if ease and appearance are what you're looking for Chicago screws could be easier an option? Really? I'm surprised. Are you saying that hand press in Springfield and Tandy is too lightweight for copper rivets and burgers? But you first came to a small hammer (Assumption) cut-off hammer in Tandy.. but you also say you wouldn't use anything less than a harbor press. I think I got confused. Have you used the bash-style pie? Besides, I don't know anything about arbor press.. but Harbor Freight has a 1/2 ton of $35 in his opinion would this be suitable for establishing leather copper rivets? Thanks, guys. Share this post FWIW; copper rivets are fixed for the first time by driving the burr down the slightly conical axis of the rivet with the use of a hole drilled in the set(er). When the burr has fallen solidly, the excess of the rivet is cut and the second part of the set is used to round that proud left portion on the donkey. I don't think the small hand press has a dye available to put the donkey, and it's definitely not powerful enough to actually 'connect' the round head you want. Peening over the rivet simply makes a disaster aesthetically, although it will keep if done properly, but that is why a rivet set is used for this type of operation. Mike. Share this post You might want to look at it. I have 2 Press-N-Snap stamps from my boat tarpaulin days with everything to fix Ligne 24 snaps. In the video, you'll see all the adjustment that happens with the Little Wonder. We sow most of everything so that we don't use rivets much and more often than not be burr rivets for force. In a production shop that uses a lot of different sizes and types of bras, a lot of small wonders set for the things you do the most and then a couple for strange things would work well. ArtShare this post ... I don't think the small hand press has a dye available to put the donkey, and it's definitely not powerful enough to actually 'connect' the round head you want. Peening over the rivet simply makes a disaster aesthetically, although it will keep if done properly, but that is why a rivet set is used for this type of operation. Mike. ... I don't think the small hand press has a dye available to put the donkey, and it's definitely not powerful enough to actually 'connect' the round head you want. Peening over the rivet simply makes a disaster aesthetically, although it will keep if done properly, but that is why a rivet set is used for this type of operation. Mike. Yes, I knew how the copper set worked, but I wasn't sure the hand press could do the operation too, and if a dye was available for both parts of the procedure - thus denying the need to buy the small hammer tool. It doesn't seem possible. I guess it doesn't matter, I was trying to do so much with the machine I want to get anyway. Is there a lot of difference in new hand presses compared to the old used ones you find in ebay? I guess finding out the size of the hole for the dyes is crucial. Also, do you use a dye at the top for certain operations? If so, how does that stay in (maybe feared)? Share this post You might want to look at it. Weaver Leather. I have this machine and it's not for burr rivets. Puse rivets Burr with a set of tools by Bob Douglas; call Vandy on .I have 2 press-N-Snap buttons from my boat log days loaded with everything to set Ligne 24 snaps. In the video, you'll see all the adjustment that happens with the Little Wonder. We sow most of everything so that we don't use rivets much and more often than not be burr rivets for force. In a production shop that uses a lot of different sizes and types of bras, a lot of small wonders set for the things you do the most and then a couple for strange things would work well. Art You might want to look at it. I have 2 Press-N-Snap stamps from my boat tarpaulin days with everything to fix Ligne 24 snaps. In the video, you'll see all the adjustment that happens with the Little Wonder. We sow most of everything so that we don't use rivets much and more often than not be burr rivets for force. In a production shop that uses a lot of different sizes and types of bras, a lot of small wonders set for the things you do the most and then a couple for strange things would work well. ArtHi Art, I like that little Wonder, I need to look at it. One question, however. when using the other tool(s) - to set copper rivets (3 pieces of Douglas tools) what happens to you next to you that you have cut and combed when you have it turned to use the "washed" rivet on the other side? It seems that you would need to sit on a rail with a hole in the center (to commune the stalk). Otherwise, the dome side can get twisted, right? Share this post The post of the rivet (which is cut) is the part that gets on top. The post is at the opposite end of the head... like a nail, and the washing machine is pushed down on it. The post has a light upholstery at the tip to help align the washing machine, but it is not likely to push it by hand. Once you drive the washing machine down in the post, you cut the excess mail, leaving just a little nut. That little girl is literally BEATEN (peened) until you deform and extend the metal to cover a part of the washing machine. Once that's done, the only way to remove the washing machine is to move all that copper that's been greased... that usually 'work hard' him. As long as you have the washing machine there, the leather is truly unlikely to work it loose. That's why they're so sure. My experience is that you need something pretty solid under the rivet, and a real hammer... It's not a sap... to make the peening. After all, you're hitting a short metal post on a wider and more metal plane. Don't be afraid to hit him. I was having difficulties with the dome part of the set until I picked up "sufficient" hammer (24oz face smooth Estwing) and flattened the post a good bit with direct impact. Then I went round it up. P.S. Don't put copper burr rivets in your stamping block...unless you're looking forward to a new stamping block. Share this post The post of the rivet (which is cut) is the part that gets on top. The post is at the opposite end of the head... like a nail, and the washing machine is pushed down on it. The post has a light upholstery at the tip to help align the washing machine, but it is not likely to push it by hand. Once you drive the washing machine down in the post, you cut the excess mail, leaving just a little nut. That little girl is literally BEATEN (peened) until you deform and extend the metal to cover a part of the washing machine. Once that's done, the only way to remove the washing machine is to move all that copper that's been greased... that usually 'work hard' him. As long as you have the washing machine there, the leather is truly unlikely to work it loose. That's why they're so sure. My experience is that you need something pretty solid under the rivet, and a real hammer... It's not a sap... to make the peening. After all, you're hitting a short metal post on a wider and more metal plane. Don't be afraid to hit him. I was having difficulties with the dome part of the set until I picked up "sufficient" hammer (24oz face smooth Estwing) and flattened the post a good bit with direct impact. Then I went round it up. P.S. Don't put copper burr rivets in your stamping block unless you're looking forward to a new stamping block. The post of the rivet (which is cut) is the part that gets on top. The post is at the opposite end of the head... like a nail, and the washing machine is pushed down on it. The post has a light upholstery at the tip to help align the washing machine, but it is not likely to push it by hand. Once you drive the washing machine down in the post, you cut the excess mail, leaving just a little nut. That little girl is literally BEATEN (peened) until you deform and extend the metal to cover a part of the washing machine. Once that's done, the only way to remove the washing machine is to move all that copper that's been greased... that usually 'work hard' him. As long as you have the washing machine there, the leather is truly unlikely to work it loose. That's why they're so sure. My experience is that you need something pretty solid under the rivet, and a real hammer... It's not a sap... to make the peening. After all, you're hitting a short metal post on a wider and more metal plane. Don't be afraid to hit him. I was having difficulties with the domotic part of the set until I picked up "sufficient" hammer (24oz face smooth Estwing) and flattened the post a bit with direct impact. Then I went round it up. P.S. Don't put copper burr rivets in your stamping block...unless you're looking forward to a new stamping block. I feel bad that you wrote everything that TwinOaks - maybe I didn't make it clear enough that I understood how the whole things work.. I already did, but thanks anyway. What I was asking was the "set to the head" that makes a dome on the opposite side. the side of the big head. What I am questioning is: when the mounted rivet turns (below the heated tip) wouldn't you need some kind of avil with a hole in the middle (to accommodate the hairstyle) while the "door dog" is doing his job? Otherwise it seems to me that the dome in the rivet could go twisted - because everything is tense at the tip of the stallion of peened under the breast. Share this post Really? I'm surprised. Are you saying that hand press in Springfield and Tandy is too lightweight for copper rivets and burgers? But you first came to a small hammer (Assumption) cut-off hammer in Tandy.. but you also say you wouldn't use anything less than a harbor press. I think I got confused. Have you used the bash-style pie? Besides, I don't know anything about arbor press.. but Harbor Freight has a 1/2 ton of $35 in his opinion would this be suitable for establishing leather copper rivets? Thanks, guys. Really? I'm surprised. Are you saying that hand press in Springfield and Tandy is too lightweight for copper rivets and burgers? But you first came to a small hammer (Assumption) cut-off hammer in Tandy.. but you also say you wouldn't use anything less than a harbor press. I think I got confused. Have you used the bash-style pie? Besides, I don't know anything about arbor press.. but Harbor Freight has a 1/2 ton of $35 in his opinion would this be suitable for establishing leather copper rivets? Thanks, guys. The seal is a solid piece of steel that can be beaten several times to form the head of the rivet. They'll probably be putting more force than the press can in one blow. You deform the rivet a little at a time. The problem with the use of manual tools to establish hardware is usually not very little strength, but too much strength and often times in the wrong direction to establish the hardware correctly. I've seen those presses in Tandy and they don't seem to be strong enough to deform copper. With a press you can only achieve the maximum force for which it is valued and once you reach that and you do not deform it has much of an option. I can't say for sure, but I'd be surprised that Crafttool's press could pull over a few hundred pounds of force. I could be wrong. You'd have to contact Crafttool to find out for real, but I'm sure if it were about half a ton I'd say in the features. The press of 1/2 tons is quite small. I can crush a #9 rivet with a little work using one though. You want to be able to do the job with the least possible effort if you're going to do a lot of them. I don't want to use a 1/2 ton in multiple rives every day. The more strength the better. Share this post I'm lost and I don't know what the hell you're talking about, there's no dome in a copper rivet - it's flat like a pancake and - if set correctly - it feels overflowing with the leather surface. The side with the burr and the peened stud feels a bit proud of the opposite surface. It's over and over with a couple of docks with a good hammer, like these pictures. Mike Share this post I'm lost and I don't know what the hell you're talking about, there's no dome in a copper rivet - it's flat like a pancake and - if set correctly - it feels overflowing with the leather surface. The side with the burr and the peened stud feels a bit proud of the opposite surface. It's over and over with a couple of docks with a good hammer. Mike. I'm lost and I don't know what the hell you're talking about, there's no dome in a copper rivet - it's flat like a pancake and - if set correctly - it feels overflowing with the leather surface. The side with the burr and the peened stud feels a bit proud of the opposite surface. It's over and over with a couple of docks with a good hammer. MikeFWIW - I have been referring to this tool made by Douglas tools (and I guess others) since Art posted the link with Sheridan Leather. Sheridan sells a set of three pieces of copper rivet tools for $55 that includes a "reputable dome". So if the copper rivets come flat to start with BUT you can tame the side of the head for a different look. That's it. Share this post Doug - - - I'm so sorry, I misunderstood or I just messed up and passed out somewhere along the way, I didn't intend to get under your skin - but the photos I took are pretty good I think. Mike Share this post Doug - - - I'm so sorry, I misunderstood or I just messed up and passed out somewhere along the way, I didn't intend to get under your skin - but the photos I took are pretty good I think. Mike. Doug - - - I'm so sorry, I misunderstood or I just messed up and passed out somewhere along the way, I didn't intend to get under your skin - but the photos I took are pretty good I think. MikeNah, you didn't get under my skin, I appreciate your entry. I like the idea of "hand" the flat side of the copper rivet even in certain articles. Here's the description of Sheridan... "This tool makes the head of the copper rivets to give your job a finished professional look. "I think I would get a small avil "cupped" (usually used for double rivets) and drill a hole in the center so that I could use this "rivet domer" tool more effectively. BTW... I wonder if this tool, the "arrowdome" is the same tool as a "fast rivet" used in the double-layered tubular rivets? It looks the same, but the domer can be more concave, not sure of that. Share this post I think it's a little bigger in diameter than the double rivet. Mike Share this post ...The press of 1/2 tons is quite small. I can crush a #9 rivet with a little work using one though. You want to be able to do the job with the least possible effort if you're going to do a lot of them. I don't want to use a 1/2 ton in multiple rives every day. The more strength the better. ...The press of 1/2 tons is quite small. I can crush a #9 rivet with a little work using one though. You want to be able to do the job with the least possible effort if you're going to do a lot of them. I don't want to use a 1/2 ton in multiple rives every day. The more strength the better. Hey, guys, I really like the idea of a harbor press to set up NON-copper's rives, stains and squids (maybe also copper rivets?). Forget about 1/2ton - there's a ton for sale at Harbor Freight right now for $48. A machine store will have to pierce some holes in it, but it is still much cheaper than one of Tandy's hand presses etc. and more versatile. Here is a great video on the subject (if you can sit through the long LaBron James add at first), it is worth a watch. I think I can get one of these. I wish there was some way to add a spring feature to the lever, but well. I wish there was some way to add a spring feature to the lever, but well. Share this post Join the conversation You can post now and register later. If you have an account, to post with your account. Note: Your mail will require the approval of the moderator before it is visible. Past as rich text. Only 75 emoji are allowed. Your link has been automatically integrated. Its previous content has been restored. You can't paste images directly. Upload or insert images from URL. Lady of leather Productions all rights reserved © 2006-2021

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Enviroflo Engineering - Enviroflo Engineering Pulse Jet Bag Filter

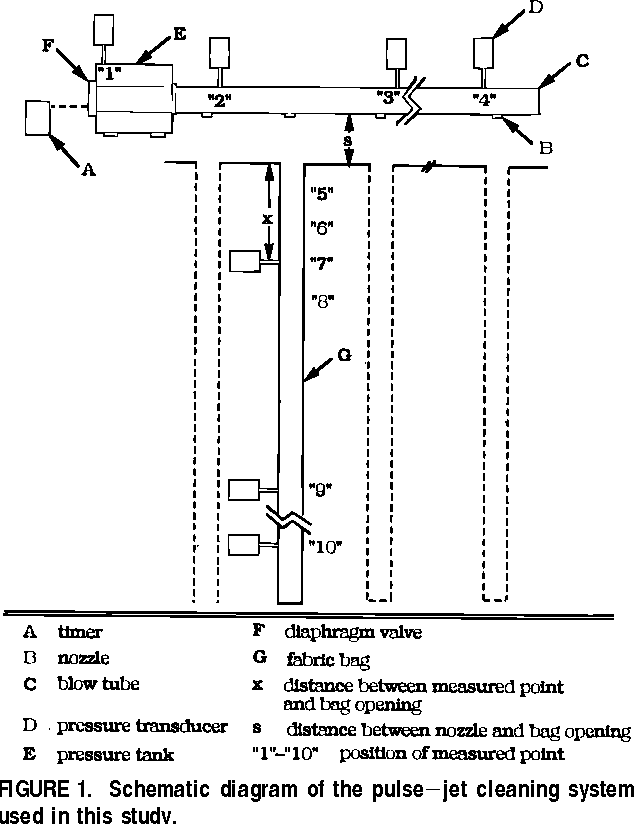

A schematic diagram of the pulse-jet bag filter test facility. | Download Scientific Diagram

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

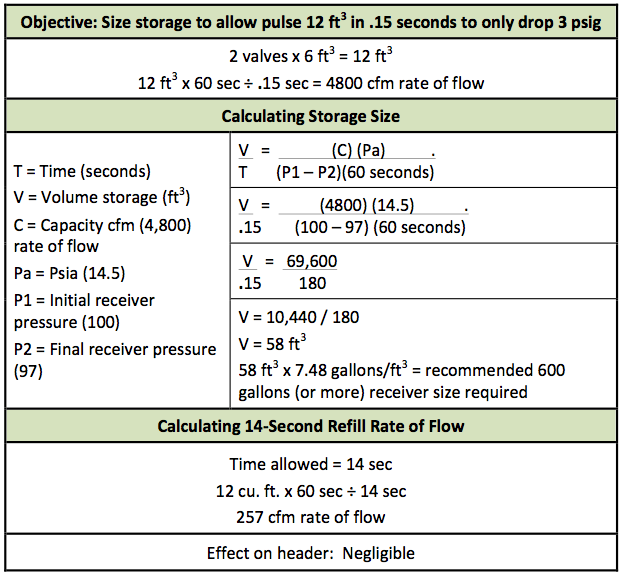

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Enviroflo Engineering - Enviroflo Engineering Pulse Jet Bag Filter

Pulse Jet Solenoid Valve - How They Work | Tameson

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Filters for pneumatic conveying - Dedusting after pneumatic transport

pulse jet bag filter design calculation

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Pulse Jet Bag Filters: The Ultimate FAQ Guide | Filson Filter

PDF) A Pilot-Scale Study of the Design and Operation Parameters of a Pulse- Jet Baghouse

Bag Filter Pulse Jet Design - DesaignHandbags

The pulse of dust collectors

Evaluation of the can velocity effect on a bag filter - ScienceDirect

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

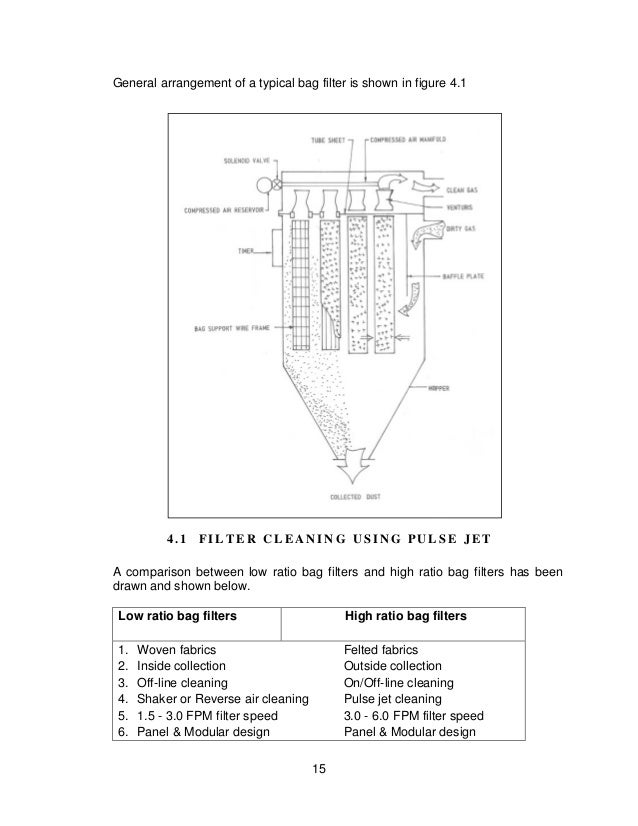

Bag Filter Calculation | Gases | Mechanics

Air blow pipe design for bag filter house, Dust bag filter house, dust collector, dust filter bag house, pulse jet bag filter housing, clean system of bag house, problem of dust collector,

DESIGN OF PLEATED BAG FILTER SYSTEM FOR PARTICULATE EMISSION CONTROL IN CEMENT INDUSTRY

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

The effect of operating conditions on resistance parameters of filter media and limestone dust cake for uniformly loaded needle felts in a pilot scale test facility at ambient conditions - ScienceDirect

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Designing and Sizing Baghouse Dust Collection Systems

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Pulse Jet Solenoid Valve - How They Work | Tameson

TEKNOFILTER 10

Compressed Air Requirement for a Bagfilter

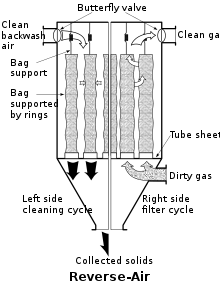

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Baghouse - Wikipedia

Getting the Dust Out: Selecting a Filtration System | powderbulksolids.com

5.8. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in th

The pulse of dust collectors

Air blow pipe design for bag filter house, Dust bag filter house, dust collector, dust filter bag house, pulse jet bag filter housing, clean system of bag house, problem of dust collector,

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Bag Filter Pulse Jet Design - DesaignHandbags

Pulse Jet Bag Filter Design: c F 0.26 m SF | Gases | Materials

Pulse Jet Bag Filters: The Ultimate FAQ Guide | Filson Filter

applied sciences

Posting Komentar untuk "pulse jet bag filter design calculation"